What Is Non-Destructive Testing (NDT)?

Non-destructive testing (NDT) refers to various inspection methods designed to allow inspectors to collect data and evaluate a system, component or material without permanently changing or harming it. If you’re in an industry that relies on NDT to assess your systems and components, you should learn more about the main NDT techniques. By being more knowledgeable about NDT, you can select the best NDT methods for your requirements.

If you want to understand NDT, find out about NDT training, learn more about its main types and what industries rely on it, keep reading.

Types of Non-Destructive Testing Applications and Common Methods

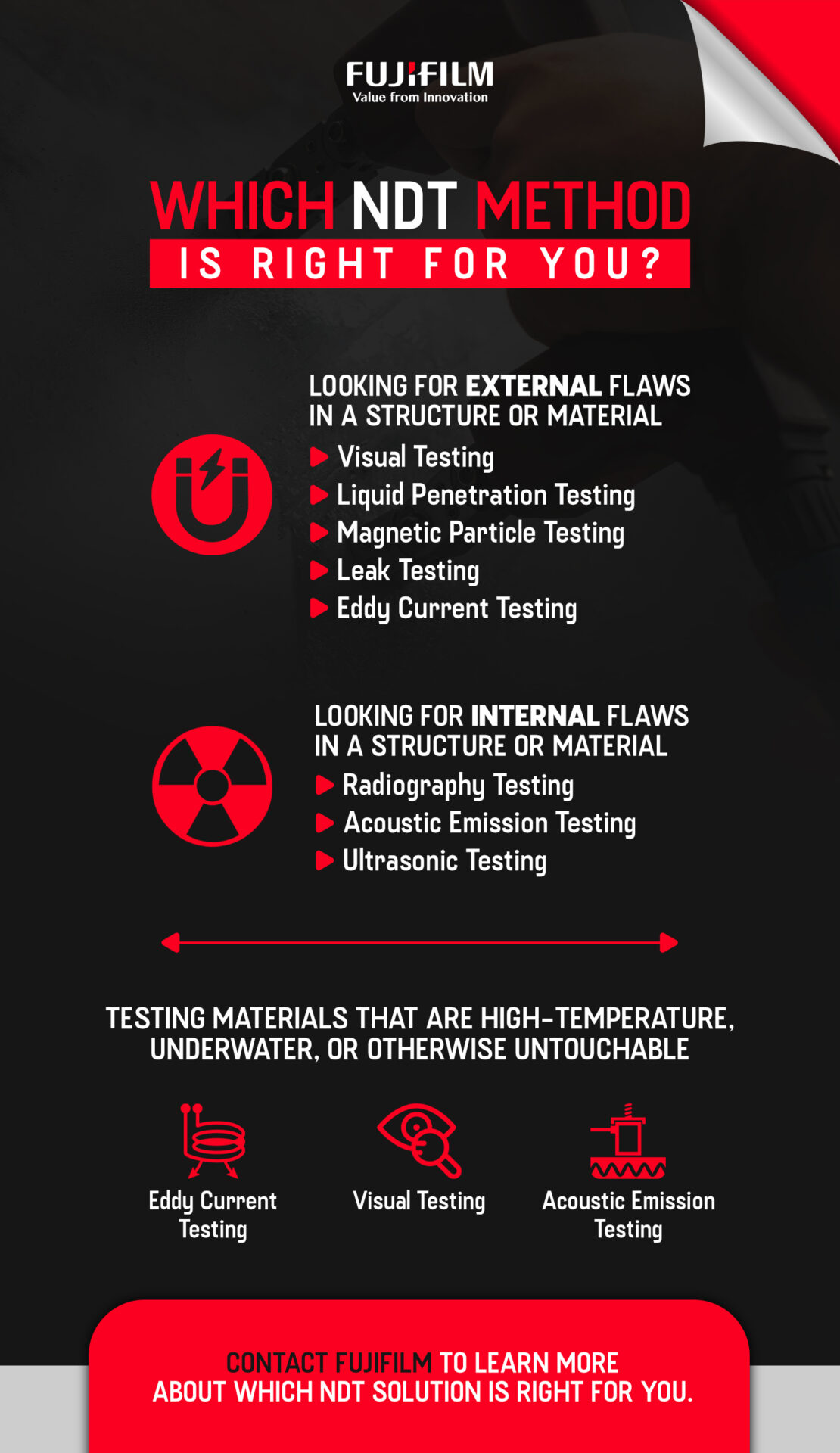

What is NDT? Since NDT is such a broad term, you may want to know more about its main applications and the standard methods for conducting tests. You can find several methods for performing NDT, and each of these methods can help you spot a material’s defects in different ways. Some of the most popular NDT methods include Leak Testing, Radiography Testing, Acoustic Emission Testing and Liquid Penetrant Testing.

Find out more about the main NDT techniques and testing methods below:

- Radiography Testing: Radiography Testing spots imperfections in a component or system through X-radiation or gamma-radiation. This kind of test uses an X-ray generator or a radioactive isotope to send radiation into a material you’re testing and onto a detector, like a film. After directing the radiation, inspectors can look at key readings from a shadowgraph created by a detector, helping them see potential issues, such as density alterations.

- Visual Testing: Visual Testing involves the collection of visual information on a material’s status. This form of testing is the most basic, as you can complete it by simply looking at an asset. For more in-depth visual inspections, you can use a Remote Visual Inspection device to get a more precise look at materials.

- Leak Testing: When you have a leaking structure or vessel, you can use Leak Testing to study the leaks and identify an asset’s defects. Inspectors often conduct leak testing with soap-bubble examinations, pressure gauges and listening devices.

- Acoustic Emission Testing: Acoustic Emission Testing refers to the process of utilizing acoustic emissions to discover an asset’s potential imperfections and defects. Much of this test involves looking for acoustic energy bursts, as these bursts indicate defects. Inspectors also examine a burst’s arrival time, location and intensity to spot potential issues.

- Ultrasonic Testing: With Ultrasonic Testing, an inspector transmits high-frequency waves into an asset or material to spot material property changes. A primary type of ultrasonic testing utilizes pulse echos. In this test, an inspector sends sounds into an asset and then measures the sound’s echos, as these echos can help them spot surface imperfections.

- Magnetic Particle Testing: Magnetic Particle Testing involves the process of spotting a material’s flaws by reviewing disruption in the material’s magnetic field’s flow. To conduct these tests, an inspector induces a magnetic field in an asset very susceptible to magnetization. Once they induce the magnetic field, they place iron particles over the material’s surface. These particles showcase any disruptions and provide visual indicators of imperfections’ locations.

- Liquid Penetrant Testing: When an inspector conducts Liquid Penetrant Testing, they’ll start by placing a coating of liquid featuring a fluorescent or visible dye over an asset. Inspectors then take off any extra solution from the asset’s surface. The remaining solution will stay in breaks in the surface, revealing any defects. After they spot any defects, they’ll remove the fluorescent dye, using ultraviolet light to examine defects. With regular dyes, inspectors will study defects via the contrast between the developer and penetrant.

- Eddy Current Testing: As a form of Electromagnetic Testing, Eddy Current Testing involves inspectors measuring a material’s magnetic field for the strength of eddy currents, sometimes referred to as electrical currents. After measuring these currents, the inspector can often spot defects in the asset or material. Particularly, inspectors look for electric current interruptions that indicate the material has imperfections.

What Industries Is NDT Used In?

Many different industries utilize NDT to ensure their materials, systems and assets are in good condition and free from defects. For example, companies employing manufacturing and fabrication processes often use NDT to ensure products have the required reliability and integrity. Those in manufacturing also use NDT to keep their products consistent and better control their manufacturing processes.

While many companies use NDT in the manufacturing phase of their products, they can also use it to ensure their machinery and other essential assets are functioning correctly. For example, a mining company might have critical components and systems they need to perform at their best. NDT allows them to check these components without worrying about harming them.

Since there are so many types of tests, you can find several industries requiring particular kinds of NDTs to comply with industry- or company-specific regulations. For instance, the American Petroleum Institute lays out NDT codes and standards for oil and gas companies. If you want to get a sense of how widely used NDT is, review some of the primary industries relying on NDT below:

- Mining

- Automotive

- Oil and gas

- Chemicals

- Aerospace

- Maritime

- Construction

- Power generation

NDT Training Services

If you’re in an industry that utilizes NDT, you might want to train key members of your team to conduct it. Since learning how to implement and document NDT properly is crucial to your assets’ performance, you should turn to a company with the expertise to train employees properly. At Fujifilm, we offer NDT training services designed to help your team in various non-destructive testing applications.

When you turn to us for your NDT training needs, you can trust us to educate your employees properly about critical tests. We currently offer regional classes for employees without any NDT experience and Level One, Two or Three certified employees in RT/Film looking to become certified in Digital Radiography. We can even come to your facility, performing on-site training to help you reduce your production downtime.

Turn to Fujifilm for Your Non-Destructive Inspection Services

If you need NDT services, you might be interested in Fujifilm. At Fujifilm, we’ve been a leading innovator in the NDT space for years. We specialize in providing digital radiography and conventional X-ray NDT products to help our customers discover any defects in their assets without harming the components they’re testing. When you partner with us, we’ll work with you to find the perfect solution from our product lineup, helping you stay on top of all your NDT needs.

Find out more about Fujifilm’s non-destructive testing products and services today. If you have any questions, please feel free to contact us.